Basic, basic construction question.

-

CaptainWacoal

- Class G

- Posts: 31

- Joined: Fri Aug 21, 2015 10:03 am

- Location: Vacaville (Nut Tree) California

Basic, basic construction question.

This is probably one of the most basic questions that anyone has ever asked the forum, but I see in a lot of construction photos that guys have taken of their projects in various stages of construction and I often see the blue vinyl protective covering left on the aluminum sheet to protect the project against bumps and scratches during construction, except for where the numerous rows of rivets are fastened. Here's the question: How do builders remove the blue vinyl in 1" rows without causing any damage, not with a razor blade? Wouldn't that score/scratch the aluminum? This cannot be how it is done. It would cause too much damage. So, how do you guys remove only 1" strips of the blue plastic without causing any damage? I am about ready to start my RV-12 empennage kit, and I would like to only remove enough blue vinyl as necessary to rivet the sheets, till I need to remove it all. Any suggestions???

-JK-

-Retired FAA/A.T.C.: SFO Tower & Bay Approach (renamed NORCAL Approach in 2002)

-Owner of a C-150/150 Texas Taildragger/Aerobat

-RV-12 kit: Empennage, Both Wings, Flight Controls, & Fuselage complete. Working on "Finish Kit"

-Retired FAA/A.T.C.: SFO Tower & Bay Approach (renamed NORCAL Approach in 2002)

-Owner of a C-150/150 Texas Taildragger/Aerobat

-RV-12 kit: Empennage, Both Wings, Flight Controls, & Fuselage complete. Working on "Finish Kit"

-

CaptainWacoal

- Class G

- Posts: 31

- Joined: Fri Aug 21, 2015 10:03 am

- Location: Vacaville (Nut Tree) California

Yeah, me neither, which is why I asked the same question 10 years ago.

http://www.rivetbangers.com/forums/viewtopic.php?t=856

http://www.rivetbangers.com/forums/viewtopic.php?t=856

- captain_john

- Sparky

- Posts: 5880

- Joined: Sun Oct 31, 2004 9:17 am

- Location: KPYM

-

CaptainWacoal

- Class G

- Posts: 31

- Joined: Fri Aug 21, 2015 10:03 am

- Location: Vacaville (Nut Tree) California

CJ,

Just out of curiosity, why do you suggests that I peel it all off now, does it get harder to peel off as it ages? Even if I use my wife's hair dryer to soften it later when I want to remove it???

Just out of curiosity, why do you suggests that I peel it all off now, does it get harder to peel off as it ages? Even if I use my wife's hair dryer to soften it later when I want to remove it???

-JK-

-Retired FAA/A.T.C.: SFO Tower & Bay Approach (renamed NORCAL Approach in 2002)

-Owner of a C-150/150 Texas Taildragger/Aerobat

-RV-12 kit: Empennage, Both Wings, Flight Controls, & Fuselage complete. Working on "Finish Kit"

-Retired FAA/A.T.C.: SFO Tower & Bay Approach (renamed NORCAL Approach in 2002)

-Owner of a C-150/150 Texas Taildragger/Aerobat

-RV-12 kit: Empennage, Both Wings, Flight Controls, & Fuselage complete. Working on "Finish Kit"

- captain_john

- Sparky

- Posts: 5880

- Joined: Sun Oct 31, 2004 9:17 am

- Location: KPYM

I suggest peeling it all off instead of doing the soldering iron thing because it ll has to come off eventually anyways. Besides, it is a waste of good building time and has no real benefit. Just build!

My two...

My two...

CJ

CJ

RV-7

Garmin G3X with VP-X & a TMX-IO-360 with G3i

It's all over but the flying! 800+ hours in only 3 years!

Garmin G3X with VP-X & a TMX-IO-360 with G3i

It's all over but the flying! 800+ hours in only 3 years!

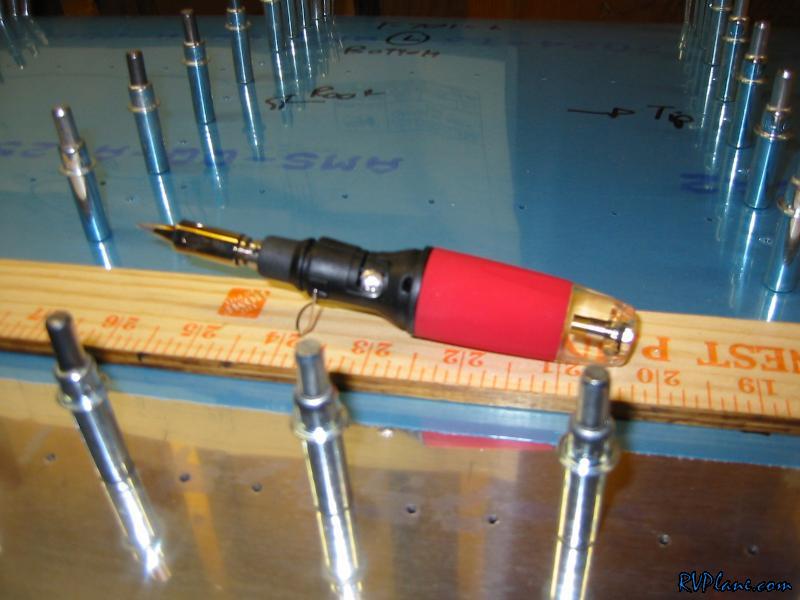

I used the soldering iron trick and it worked quite well. I started with an electric iron (35w+), and it worked very well. I upgraded to a butane soldering iron:

This variety of soldering iron worked much better than the electrical one. It is much lighter, completely portable, and much hotter, which means you can get the vinyl off much quicker.

Also, to get straight lines, use a cheap wood yardstick. The metal ones conduct too much heat and make the soldering iron much less effective.

I left the vinyl on until the very last minute in order to protect the skins. I would do it again this way if I did another build.

This variety of soldering iron worked much better than the electrical one. It is much lighter, completely portable, and much hotter, which means you can get the vinyl off much quicker.

Also, to get straight lines, use a cheap wood yardstick. The metal ones conduct too much heat and make the soldering iron much less effective.

I left the vinyl on until the very last minute in order to protect the skins. I would do it again this way if I did another build.

Mike Bullock

http://www.rvplane.com

RV-7 | Superior IO-360 | Whirlwind 200RV

Garmin GTN650 | GRT Dual Sport SX EFIS

Status: FLYING!

http://www.rvplane.com

RV-7 | Superior IO-360 | Whirlwind 200RV

Garmin GTN650 | GRT Dual Sport SX EFIS

Status: FLYING!