Page 1 of 2

Metal Oil Door

Posted: Mon Aug 25, 2008 10:42 pm

by bullojm1

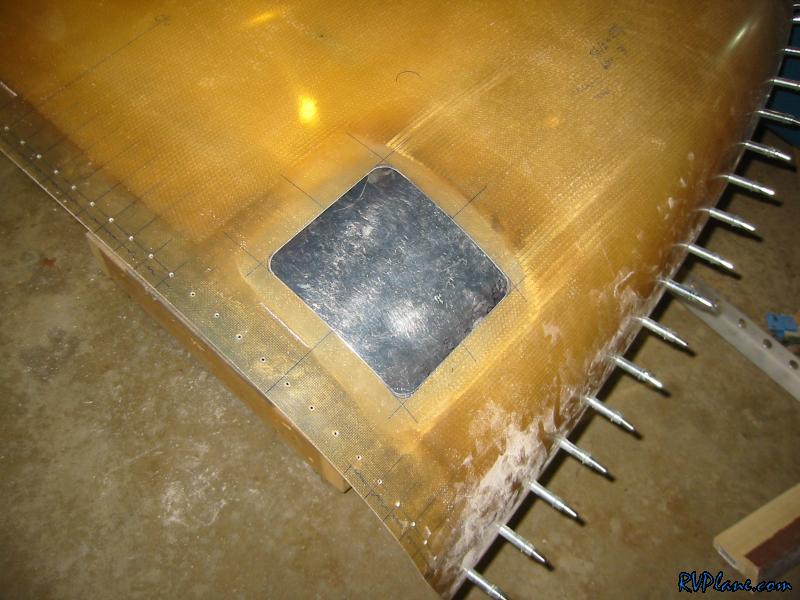

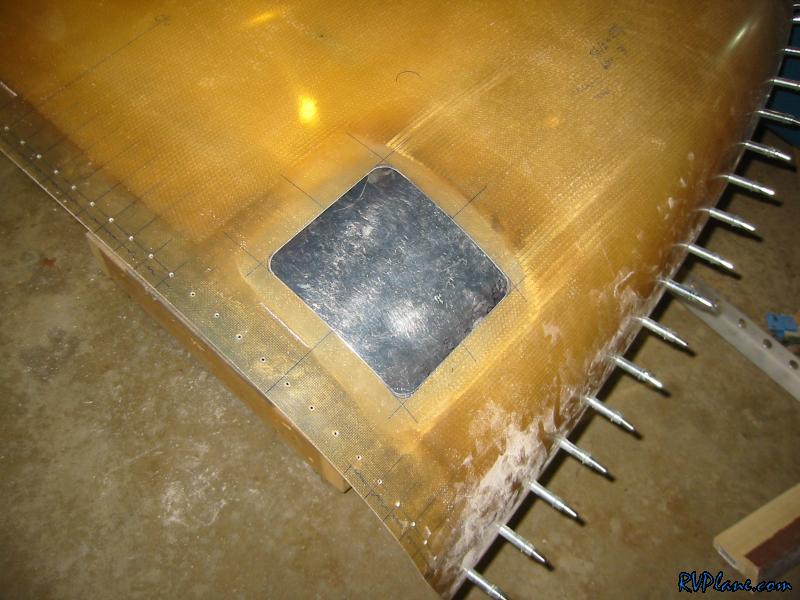

I banged out a metal oil door tonight. Since I have the Sam James cowl, I didn't get an extra oil door like the Van's cowl comes with. Instead of trying to fab something out of fiberglass, I thought the metal hatch would be a perfect solution. Mine turned out really great:

I am waiting on some concealed hinges before I mount it to the cowl perminantly. I will put a single Hartwell H-5000-2 latch (the only thing I bought at Osh!) on the bottom and call it done. I think I might polish the hatch and leave it unpainted. It looks awesome!

Posted: Tue Aug 26, 2008 8:30 am

by Spike

Very nicely done guy!

Posted: Tue Aug 26, 2008 8:47 am

by cjensen

Nice Mike! I'll probably do the same thing...

Posted: Tue Aug 26, 2008 8:56 am

by bullojm1

cjensen wrote:Nice Mike! I'll probably do the same thing...

Chad-

Check out my web log on the details:

http://rvplane.com/?categoryid=6&dayid=642

The main thing you need to do is make the first cut of the sheet WAY larger than the oil door (mine was 3" larger in every direction) to give you more leverage in all directions for the bend. If you make the metal door the final size right off the bat, you won't have a good curve on the edges. Dick Martin gets the credit for that idea. I spoke with him extensively at Osh about all the neat mods he had on his RV-8.

Posted: Tue Aug 26, 2008 9:44 am

by cnpeters

Mike,

How will it be opened? A latch still to be installed or internal remote cable?

Posted: Tue Aug 26, 2008 10:06 am

by bullojm1

cnpeters wrote:

How will it be opened? A latch still to be installed or internal remote cable?

Carl-

I will put a Hartwell latch on it eventually. I need to wait for an order of concealed hinges before I can mount it permanently to the cowl. Once it is hinged, then I will cutout the hole for the latch. Here is the latch I am going to use:

- Mike B

Posted: Tue Aug 26, 2008 11:21 am

by cjensen

bullojm1 wrote:Chad-

Check out my web log on the details:

http://rvplane.com/?categoryid=6&dayid=642

The main thing you need to do is make the first cut of the sheet WAY larger than the oil door (mine was 3" larger in every direction) to give you more leverage in all directions for the bend. If you make the metal door the final size right off the bat, you won't have a good curve on the edges. Dick Martin gets the credit for that idea. I spoke with him extensively at Osh about all the neat mods he had on his RV-8.

Will do! Thanks!

Posted: Tue Aug 26, 2008 11:45 am

by bullojm1

Chad-

Another thing - Guden made me order a $25 minimum of concealed aluminum latches (3.99 ea). Since I bought 8 of them, I will probably sell off two or three sets at cost once I get them and make sure they work. You interested in a set?

Posted: Tue Aug 26, 2008 11:48 am

by cjensen

Not sure what they are...got a pic? I can do some research to see if it's what I want. I'm thinking I'm going to do a remote release, and would need to know if they would work with that.

Posted: Tue Aug 26, 2008 12:20 pm

by bullojm1

Checkoway mentioned he liked these hinges, although I haven't seen anyone else who has used them:

Guden NHAL9290

They should work fine with a remote release. Obviously I will let you know how well they worked once I get them drilled. Or maybe I will lie so you can still buy them off me

Posted: Tue Aug 26, 2008 2:39 pm

by cjensen

I'd be interested in two...once you get them installed with pics!

Posted: Tue Aug 26, 2008 6:06 pm

by painless

I used the same hinges and latch. Both work great and should make the door you made look and work great Mike!

Posted: Tue Aug 26, 2008 10:44 pm

by cnpeters

Mike - put me in for two also. When the time comes, you can just ship to one of us as Chad and I live a couple miles apart. BTW, I've never perused your website before - very nice! It's going in my top builder's bookmark list despite your bizarre taste in aeronautical wheel configuration

.

Posted: Wed Aug 27, 2008 5:41 am

by papakeith

nice job. I'm curious, did you use anything to help make the bend or did you just keep bowing it until it was correct?

Posted: Wed Aug 27, 2008 8:58 am

by bullojm1

cnpeters wrote:

Mike - put me in for two also. When the time comes, you can just ship to one of us as Chad and I live a couple miles apart. BTW, I've never perused your website before - very nice! It's going in my top builder's bookmark list despite your bizarre taste in aeronautical wheel configuration

.

Carl-

Sounds like a plan to me! I will make sure the hinges work first, then arrange 4 of them to go to Normal, IL. You know, originally I was going to make a -7A. However, I decided it was better to ground loop than flip over

.

papakeith wrote:nice job. I'm curious, did you use anything to help make the bend or did you just keep bowing it until it was correct?

Keith-

The oil door is 5.5" by 6", however, the original sheet I used to bend was 11.5" by 12" to give me more me more leverage to make the bend as well as have the bend continue on the cut line. If I made the door 5.5"x6" right off the bat, it would of been much harder to bend and the bend wouldn't of continued to the edges. To make the bend I did it all by hand. Took a lot more force than I thought to bend the 050! Since it is a somewhat compound shape, I needed to clamp one side down to the table to cause one side to have a tighter radius bend than the other. All in all, it took about an hour to bend the door. Once the door is in for good, I am going to put a stiffener on the bottom of it to keep it in place.

Posted: Wed Aug 27, 2008 9:57 am

by hydroguy2

Mike, are all the hinges spoken for? If not, I would like a pair.

do you need a trim knob?

Posted: Wed Aug 27, 2008 10:11 am

by bullojm1

hydroguy2 wrote:Mike, are all the hinges spoken for? If not, I would like a pair.

do you need a trim knob?

Brian-

I *might* have an extra pair available. If I screw up one of them, then I won't. If everything goes perfectly, I will have an extra pair I will send ya!

Your trim knob does look awesome! However I am all electric - I can't be an Electrical Engineer and have manual trim!

Posted: Wed Aug 27, 2008 11:02 am

by hydroguy2

bullojm1 wrote: [........... If everything goes perfectly, I will have an extra pair I will send ya! ......... However I am all electric - I can't be an Electrical Engineer and have manual trim!

Super thanks. If you want a custom widget (knob) for something else let me know, maybe I can help.

I thought about electric trim, but I know my limits and wiring isn't one of them. I wanted my trim to always work.

Posted: Wed Aug 27, 2008 11:37 pm

by cnpeters

bullojm1 wrote:

Carl-

Sounds like a plan to me! I will make sure the hinges work first, then arrange 4 of them to go to Normal, IL. You know, originally I was going to make a -7A. However, I decided it was better to ground loop than flip over

.

[

I retracted my comment to Chad and Larry Enyeart who came over tonight and helped attach one of the wings - the bottom 7/16" bolts/nuts are a bitch to get on all interwined with the gear mount. Not much room there. I hear ya' on the flip over - I don't think I will mess with grass strips.

The verdict is in!

Posted: Fri Aug 29, 2008 11:06 pm

by bullojm1

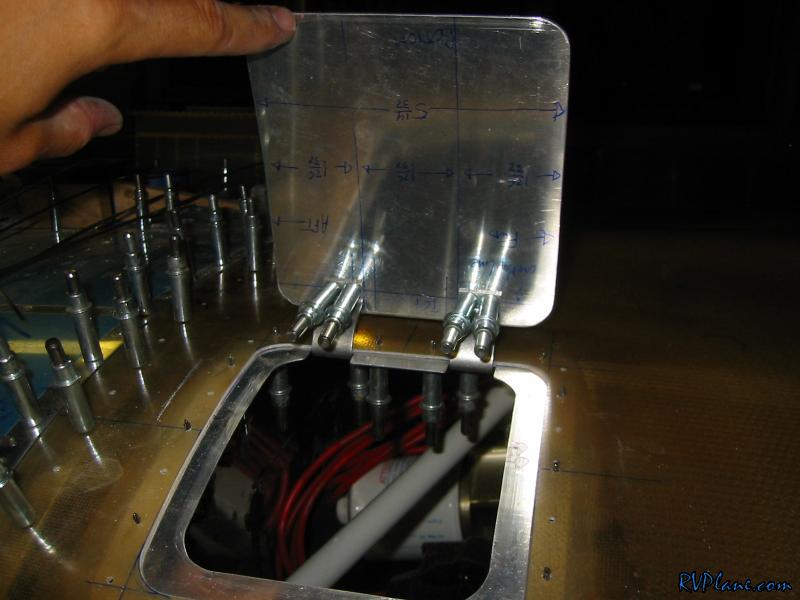

I received the aluminum hinges from Guden on Wednesday and got around to installing them tonight. They are PERFECT for this application. My whole builders log entry for all of the details is at:

http://rvplane.com/?categoryid=6&dayid=644

Last I checked Carl, Chad and Brian (hydroguy2) called dibs on the 6 hinges I have left over. 8 hinges after shipping ran me $37.68 - or $4.71 each. My thought is email me your addresses (I know I can send Carls and Chads in the same box) to

mike@rvplane.com and I will send them out and email you guys back with the total cost after the actual shipping. Send me a check for whatever that amount is and call it done! Sound fair?