Sam James Cowl and IO-360 Problem and Solution

Posted: Sat Oct 25, 2008 10:39 am

I have a unique combination of engine/cowl that I thought I would document for anyone in the group that might be going down this path. The way I figure it is there is no sense in someone else relearning the issues that I ran into......or someone might want to stay away from this combination because of the additional work.

My engine is a Superior XP-IO-360-B1A1 (Non roller tappet, Fuel Injected, Vertical Induction 180 HP engine) and my cowl is the Sam James short cowl (so I wouldn't need a prop extension).

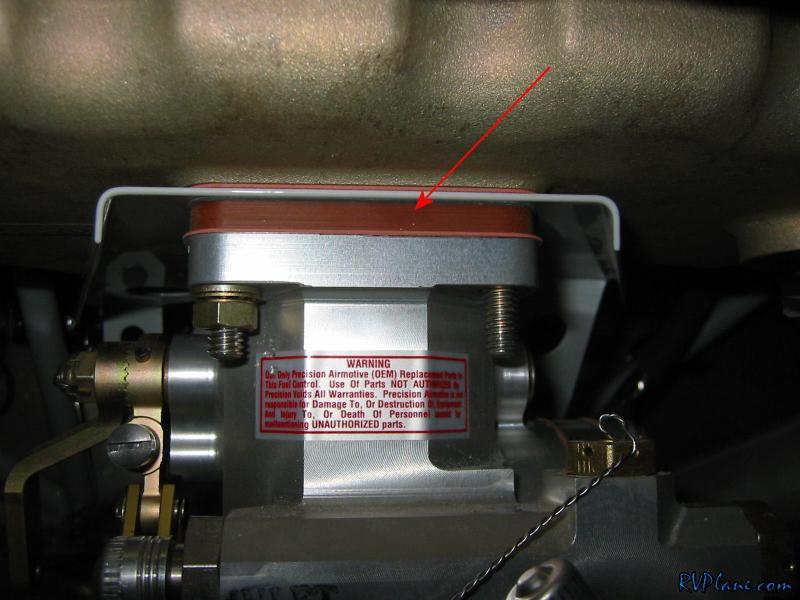

First off, a word on safety on this engine. There is a thermal isolation spacer that goes between the sump and the fuel controller. The purpose of this spacer is to thermally isolate the fuel controller from the oil sump. This is to keep the fuel controller from being heated by the sump, which could possibly cause vapor lock in the fuel controller. Evan at Superior said he knew of some builders that omitted this spacer and they didn't run into any problems.

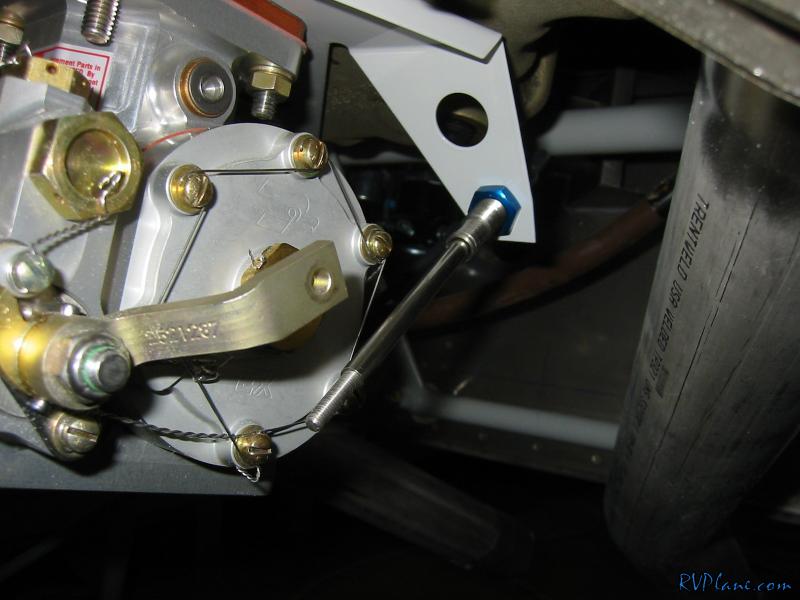

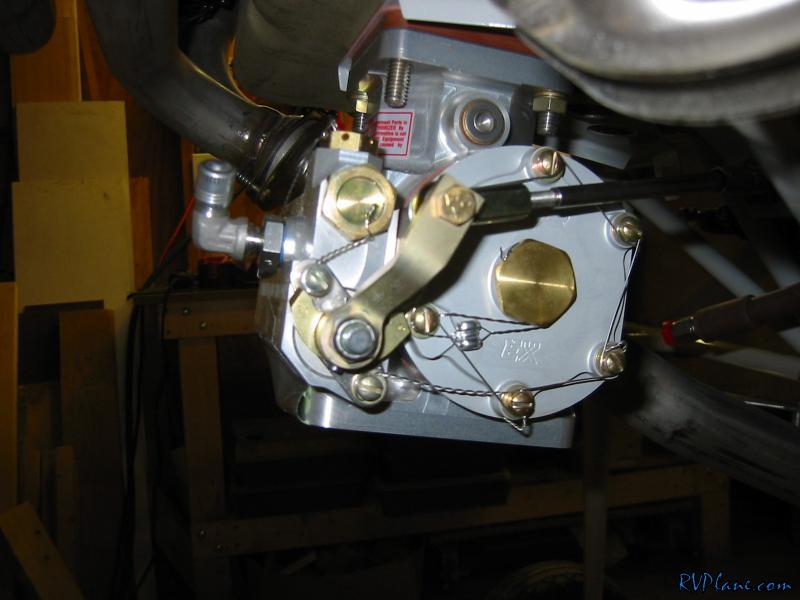

The next issue of the mixture arm alignment. Van's sells a special powder-coated bracket (VA-182-PC KIT) for the vertical induction fuel injection controller. However, as the following picture shows (cable and arm in idle cutoff position), things don't line up as they should.

It's even worse in the full rich position:

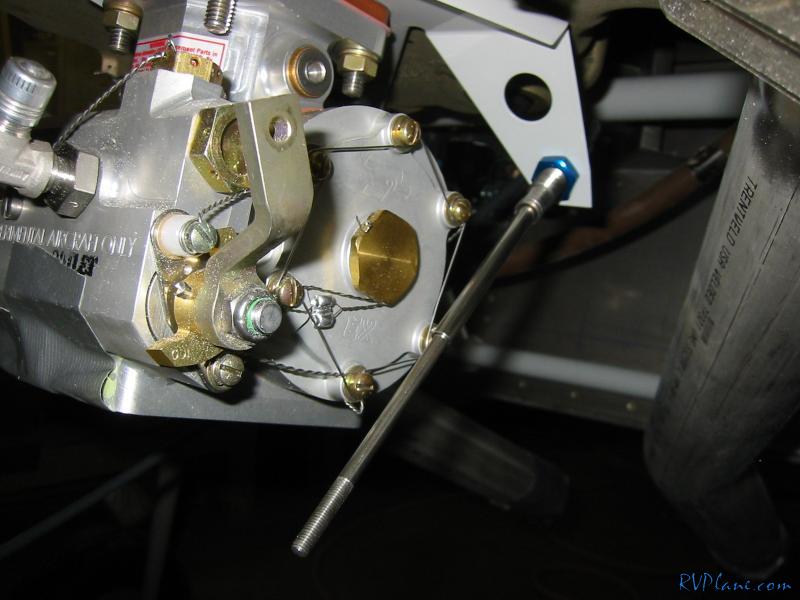

The solution to this problem is to bend the bracket about 20-30 degrees AND adjust the position of the arm on the controller. Here is the bent bracket:

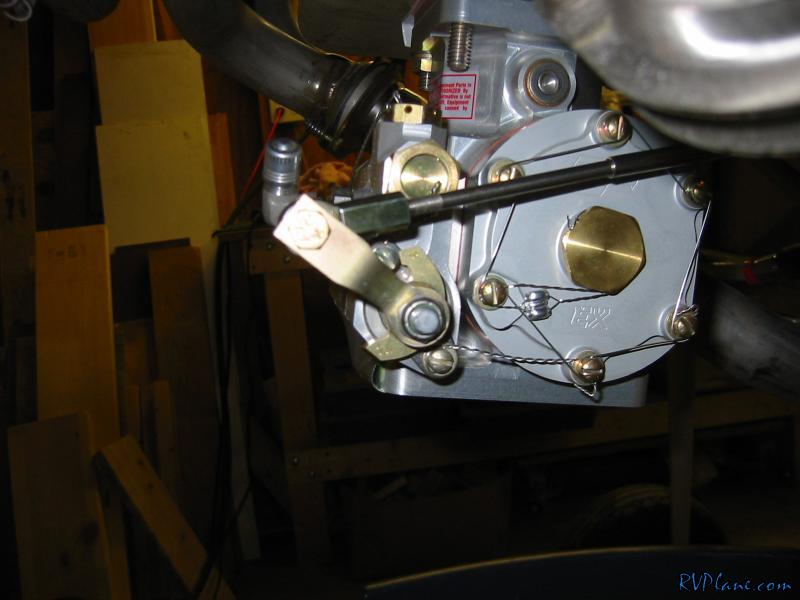

And more pics of the controller with the adjusted arm. Here is full rich:

And idle cutoff:

So with all of that solved, there is still another issue to deal with. The Sam James cowl (I don't know if the Van's cowl has the same issue?) interferes with the mixture arm. The reason for this is the IO-360's servo is offset to the left of the engine. I have NO idea why it isn't centered, but it is. Here is the hole I needed to put into the cowl for the mixture arm to not interfere:

And another shot from the front:

So I have this nice hole in my cowl. I need now to make a fiberglass bubble over it to cover it up. I couldn't for the life of me figure out how to side the proper bubble with the cowl off the engine. Then it came to me -- glass it in place with the cowl on the engine. I needed to make a mold out of clay for the initial shape, so I put some duct tape over 1/2 of the hole and a plastic bag over the mixture arm to act as a backing for the clay.

Next I put some modeling clay (non drying clay, purchased at a craft store) over the hole and made a somewhat aerodynamic shape.

After some more prep work (sanding and waxing - see my site for details - http://rvplane.com/?categoryid=6&dayid=666) I layed up an initial three layers of glass cloth:

So, if you are thinking about this engine/cowl combination, be aware there is a little extra effort involved and your cowl isn't going to be perfectly symmetrical. However, as obtrusive as this modification may seem, it is barely noticeable when looking at the cowl while standing up. I was really surprised at how concealed it was.

My engine is a Superior XP-IO-360-B1A1 (Non roller tappet, Fuel Injected, Vertical Induction 180 HP engine) and my cowl is the Sam James short cowl (so I wouldn't need a prop extension).

First off, a word on safety on this engine. There is a thermal isolation spacer that goes between the sump and the fuel controller. The purpose of this spacer is to thermally isolate the fuel controller from the oil sump. This is to keep the fuel controller from being heated by the sump, which could possibly cause vapor lock in the fuel controller. Evan at Superior said he knew of some builders that omitted this spacer and they didn't run into any problems.

The next issue of the mixture arm alignment. Van's sells a special powder-coated bracket (VA-182-PC KIT) for the vertical induction fuel injection controller. However, as the following picture shows (cable and arm in idle cutoff position), things don't line up as they should.

It's even worse in the full rich position:

The solution to this problem is to bend the bracket about 20-30 degrees AND adjust the position of the arm on the controller. Here is the bent bracket:

And more pics of the controller with the adjusted arm. Here is full rich:

And idle cutoff:

So with all of that solved, there is still another issue to deal with. The Sam James cowl (I don't know if the Van's cowl has the same issue?) interferes with the mixture arm. The reason for this is the IO-360's servo is offset to the left of the engine. I have NO idea why it isn't centered, but it is. Here is the hole I needed to put into the cowl for the mixture arm to not interfere:

And another shot from the front:

So I have this nice hole in my cowl. I need now to make a fiberglass bubble over it to cover it up. I couldn't for the life of me figure out how to side the proper bubble with the cowl off the engine. Then it came to me -- glass it in place with the cowl on the engine. I needed to make a mold out of clay for the initial shape, so I put some duct tape over 1/2 of the hole and a plastic bag over the mixture arm to act as a backing for the clay.

Next I put some modeling clay (non drying clay, purchased at a craft store) over the hole and made a somewhat aerodynamic shape.

After some more prep work (sanding and waxing - see my site for details - http://rvplane.com/?categoryid=6&dayid=666) I layed up an initial three layers of glass cloth:

So, if you are thinking about this engine/cowl combination, be aware there is a little extra effort involved and your cowl isn't going to be perfectly symmetrical. However, as obtrusive as this modification may seem, it is barely noticeable when looking at the cowl while standing up. I was really surprised at how concealed it was.