Fuel line fittings

Fuel line fittings

What are or where can I find the torque values for the fuel line fittings?

Jorge Fernandez

N214JL(Reserved)

9A QB

N214JL(Reserved)

9A QB

-

Spike

- Chief Rivet Banger

- Posts: 4013

- Joined: Thu Oct 14, 2004 8:40 pm

- Location: Baltimore, MD

- Contact:

Did you try AC43.13?

http://www.rivetbangers.com - Now integrating web and mail!

Current Build: 2 years into a beautiful little girl

Current Build: 2 years into a beautiful little girl

- captain_john

- Sparky

- Posts: 5880

- Joined: Sun Oct 31, 2004 9:17 am

- Location: KPYM

Great question, I've heard everything from tighten it one flat after contact to REAL tight. Not very scientific. Hope someone has a good asnswer for you on this.

I'll be watching

JohnR

RV-7A - Fuselage - SOLD, just not supposed to be

Numbers 6:24 - The LORD bless thee, and keep thee

RV-7A - Fuselage - SOLD, just not supposed to be

Numbers 6:24 - The LORD bless thee, and keep thee

- Wicked Stick

- Class B

- Posts: 1000

- Joined: Wed Feb 09, 2005 10:00 pm

- Location: KEWB

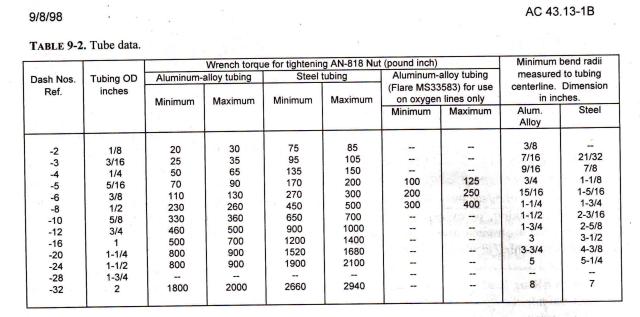

Well as with most projects there is an area covered that's closer to an art than science and it looks like fuel line fittings is it on this one. I went over to the airport and talked with my favorite A&P yesterday and he copied a sheet with lots of info about fittings Aluminum and Steel for us. Once my camera and I share the same space I'll get a jpeg of it and post a link to the picture of the sheet for all to download. For right now I will put the info for 3/8" fitting Aluminum (probably the one needed). Torque limits in INCH POUNDS Min.-110 Max.-130. Pretty light torque. When I asked him about this this he said you do a lot of fuel lines and you just get a feel for it. Indicating to me there's an art to it.

- Cherokee Driver

- Class E

- Posts: 144

- Joined: Sun Sep 18, 2005 10:43 am

- Location: Waukesha, Wisconsin

- Contact:

- captain_john

- Sparky

- Posts: 5880

- Joined: Sun Oct 31, 2004 9:17 am

- Location: KPYM

Cool, CD!

You musta scanned it from 43.13 yourself?

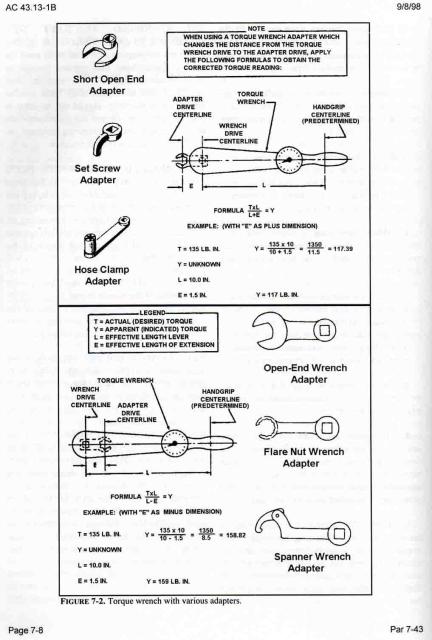

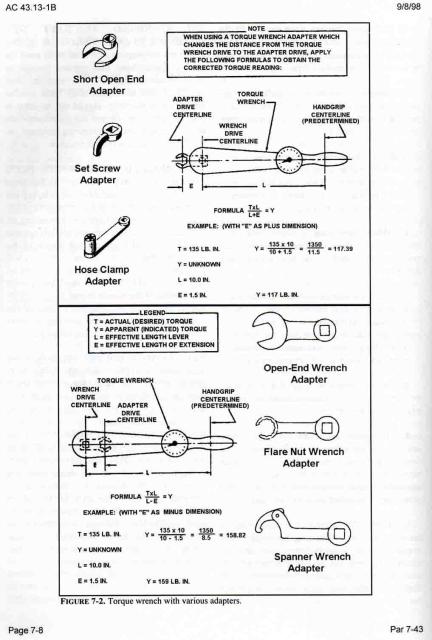

Tell me, do you plan on doing the calculations for the crowsfoot wrench and all that stuff?

I am thinking that once a "feel" for torque is found, that may be enough?

Whacha gonna do?

CJ

CJ

You musta scanned it from 43.13 yourself?

Tell me, do you plan on doing the calculations for the crowsfoot wrench and all that stuff?

I am thinking that once a "feel" for torque is found, that may be enough?

Whacha gonna do?

RV-7

Garmin G3X with VP-X & a TMX-IO-360 with G3i

It's all over but the flying! 800+ hours in only 3 years!

Garmin G3X with VP-X & a TMX-IO-360 with G3i

It's all over but the flying! 800+ hours in only 3 years!

- Cherokee Driver

- Class E

- Posts: 144

- Joined: Sun Sep 18, 2005 10:43 am

- Location: Waukesha, Wisconsin

- Contact:

Actually, I am sort of a reference hound. I have been collecting books and reference stuff for a couple of years. My mechanic instilled in me a curiosity in doing things by the book so I picked up a lot of books, and I refer to them often. When I see a post that is looking for something I may have on file, I feel a need to do the research and share it. As for the Crows foot calculations

I'll let you guys do the math.

CD

I'll let you guys do the math.

CD

RV-8A

Wing Kit (Slow Build...very slow build)

Home of "Skunk Works, Wisconsin Branch"

"Glacial Pace...but lovin every minute of it!"

Wing Kit (Slow Build...very slow build)

Home of "Skunk Works, Wisconsin Branch"

"Glacial Pace...but lovin every minute of it!"

That's a nice bunch of numbers to crunch. It doesn't have to be that cumbersome though. The picture below is the actual combo I used to tighten the nuts at the bottom of the spar carry through.

So the way you arrive at the ratio is this. D1 plus D2 divided by D1 gives you your ratio. Pick a number on your torque scale and multiply it by your ratio. If it falls into the torque range you like use it. If not keep looking for a number that does. For instance with the set up shown it took a setting of 33 inch pounds to give me just a smidge less than a 70 inch pound torque. Or divide the desired torque by the ratio and the result is is the torque to set the wrench to.

So the way you arrive at the ratio is this. D1 plus D2 divided by D1 gives you your ratio. Pick a number on your torque scale and multiply it by your ratio. If it falls into the torque range you like use it. If not keep looking for a number that does. For instance with the set up shown it took a setting of 33 inch pounds to give me just a smidge less than a 70 inch pound torque. Or divide the desired torque by the ratio and the result is is the torque to set the wrench to.

Last edited by jim_geo on Tue Sep 05, 2006 2:02 am, edited 1 time in total.

Thanks for all the help guys. When it comes to calculating torque with an extension, go to our friend Checkoway's site and use this handy dandy calculator: http://www.rvproject.com/mechanic.html. Higher math gives me a headache.

Jorge Fernandez

N214JL(Reserved)

9A QB

N214JL(Reserved)

9A QB