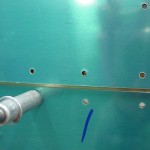

When the left LE assembly is installed on the spar, the row of holes that attach the skin to the spar on the bottom side of the wing align perfectly. The matching row on the upper surface of the wing has the skin offset forward (up) by about 1/2 diameter, and a corresponding sizable gap between the LE skin and the main top skin. Maybe I need to step back and take a fresh look, but I just can't see anything that's wrong. The gap is consistent down the entire length of the LE.

Put the right LE together to see if it had the same problem...went together fine, and lines up perfectly on the wing, so the problem is with the left assembly only. If I force it into alignment with clecoes, it bows the rib flanges inside, which can't be correct.

Full log & pictures on my build log here.

Any 9 builders know the secret to this? I'm ready to move on to fuel tanks!

-Joshua