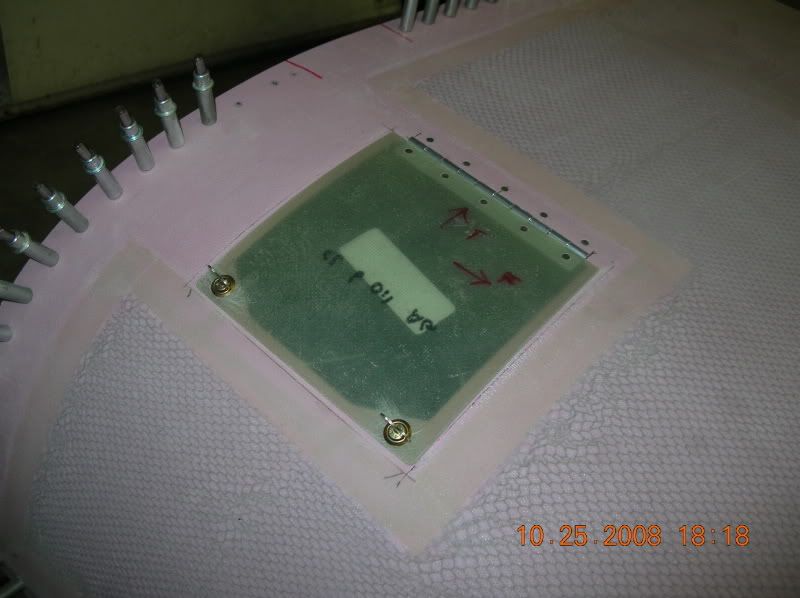

A few days ago I completed the oil door install. Since I am poor and trying to save for avionics, I went standard Vans on the hinge and the fasteners. Cheap, works and does not look that bad!

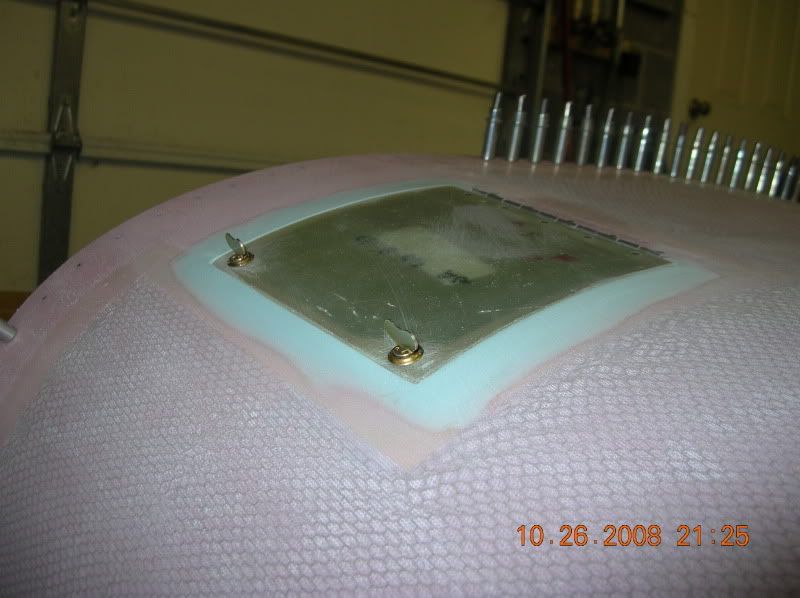

I cut the door undersize to get it down on the flat part of the molded in recess and then used packing tape and Superfill to fill and fair in the door. Looks pretty good.

This gave me a square edge around the door opening which looks much better. Not sure why Van's does not mold the recess with square edges instead of radiused ones.

If I had it to do over, I would not cut the hole in the cowl until after I had the door sized. I still have a nice flange around under the door but it was close on the camlocks.